Thermostatic Mixing Valves (TMVs) – choosing, adjusting, installing and preventing Legionella

TMV stands for Thermostatic Mixing Valve, a fitting installed to control the temperature of water coming from a tap or showerhead. It’s an essential component of plumbing installation in a commercial washroom setting that protects users from scalding.

The difference between mixer taps and Thermostatic Mixing Valves

In all buildings, particularly large ones such as hospitals and schools, maintaining a consistent water temperature throughout the property can be challenging. By fitting thermostatic mixing valves, the flow of water is regulated to a safe temperature throughout the site.

You may have heard the term 'mixer tap' before, which refers to a single tap that provides both hot and cold water. Often, this tap will have a control that allows you to slide the opening between hot and cold water. However, you should not confuse a TMV with a mixer tap.

While mixer taps or showers allows you to adjust the temperature of the water coming out of the tap, the TMV is directly responsible for the temperature of the hot water feed before it reaches the tap, regardless of whether it is a mixer or not.

How a Thermostatic Mixing Valve Works

A thermostatic mixing valve works by blending a mains hot and a mains cold feed into a single warm feed. In some cases, one TMV can be used to supply up to three or four outlets; however, it’s essential to note that the further an outlet is from the TMV, the lower the temperature will be.

A TMV can also immediately shut off the hot water flow through the valve if the cold supply ever fails. This is vital as it could save a user from being scalded.

It should be noted that one of the downsides of a TMV is that the warm water temperature produced is ideal for bacteria, such as Legionella, to grow. For this reason, it is recommended that a TMV is installed as close to the water outlet (Tap or Commerical Shower) as possible to minimise the amount of pipe containing mixed warm water.

TMV2 or TMV3?

There are two types of thermostatic mixing valves, TMV2 and TMV3. Your common TMV2 is the type of valve commonly used in domestic environments, although it is also sometimes used in small business settings. They work with water pressures from 0.1 to 5 bar.

TMV3 is a commercial-grade mixer valves that work with pressures up to 10 bar. These are specifically designed for commercial environments and are required in hospitals, schools, and healthcare settings. TMV3s are needed to adhere to NHS D08 regulations. While TMV2 still meets two main British standards, it can’t be used in healthcare settings. TMV3s are more robust and influential, making them essential for commercial-grade washrooms, showers, and changing rooms.

Our most popular thermostatic mixing valves are the Intamix TMVs and the Bristan Sirrus TMV. Both are regulated to TMV3 standards. For installations with limited space, we recommend the Delabie Compact Nano TMV3 Thermal Mixing Valve.

Where to Install a Thermostatic Mixing Valve (TMV)

Understanding thermostatic mixing valves (TMVs) and their installation is a critical aspect of any commercial washroom installation. Equally, purchasing the correct size and type will help to comply with the necessary regulations.

Faced with the legislation and red tape involved with any commercial environment, you’re sure to run into items, phrases and requirements that you’ve never even heard of before. Enter the washroom and you’ll continue to be faced with a litany of Building Regulations and environmental health concerns that make the whole ordeal seem pretty daunting.

However, while you’re navigating your grab rails and figuring out whether you need to comply with Document M of the Building Regulations, it’s worth getting to grips with thermostatic mixing valves, as these are used throughout all commercial washroom settings.

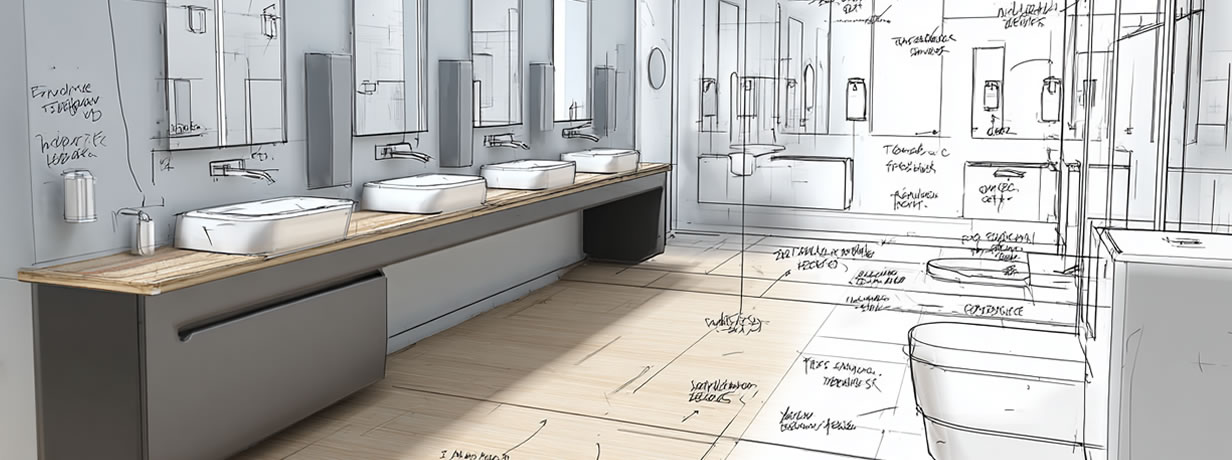

Typically, thermostatic mixing valves are located beneath the wash basin or within the vanity unit, adjacent to a shower, in a commercial setting. Some sophisticated taps and showers also feature thermostatic mixing valves integrated into the unit's body.

In some scenarios, a thermostatic mixing valve may have been used to service more than one wash basin, in which case the TMV may not be directly beneath the hand-wash area. If you are installing TMVs as part of a new refurbishment project, you can see our guide on how to install a TMV.

How to Install a Thermostatic Mixing Valve

For best practice, a thermostatic mixing valve should be fitted to each tap or shower outlet in your washroom. It is worth noting that the regulations governing the installation of a TMV in a domestic setting differ from those in a commercial washroom environment. A commercial toilet or shower room requires a minimum of a TMV3 valve and not a TMV2. The Commercial Washrooms sales team will be able to help guide you on what is needed; however, further clarification can be found in one of our earlier blogs: What is a TMV and how does it work?

TMV valves should be installed in the pipework just before the tap or shower outlet to avoid long runs of pipe where the water temperature can excessively cool. We suggest leaving adequate space beneath the washbasin and taking your TMV3, then fitting both the hot and cold feeds to it. Your valve will have an outlet left, which is where the resulting warm water is to be fed and installed to your hot tap.

In some instances, people have installed a single thermostatic mixing valve, such as the 15mm Intamix TMV3 thermostatic mixing valve, on the hot feed supplying a whole row of washbasins. However, this is poor practice, and if the TMV3 fails or gets blocked, then the whole row of washbasins will be out of action. We recommend using one TMV for each hot tap or shower.

Thermostatic mixing valves and showers

Thermostatic mixing valves used in showers are the same as those used to regulate the temperature of tap water. Installing a TMV3 for a shower requires a professional and is fundamental to the health and safety of your users. Of course, at peak times in places like gyms or leisure centres, the demand for hot water is excessive. In certain circumstances, this can result in your hot water being completely drained.

However, with the required use of a thermostatic mixing valve, the hot feed to your shower has already been blended with cold mains water. This warm water feed now pulls less hot water for the shower, helping to protect your reserves while simultaneously preventing scalding.

How To Adjust A Thermostatic Mixing Valve (TMV)

What temperature should my hot water be?

Hot water must be stored at a minimum temperature of 60 °C to kill Legionella and other harmful bacteria. There will be a drop in temperature by the time it reaches the pipes and exits the tap, but ordinarily, we would expect this drop to be about 10 °C. The recommended temperature for hot water in a commercial setting is 50 °C, with healthcare settings typically set slightly higher at 55 °C.

A TMV will blend the hot and cold water to a safe 40-42 degrees and should be installed as close to the tap or shower outlet as possible to minimise any heat loss through the pipes.

To reduce the risk of the plumbing system harbouring Legionella bacteria and thereby causing Legionnaires' Disease, consider using a TMV with a built-in sterilisation system, such as the Inta Anti-Legionella TMV. This provides an opportunity to flush the valve, pipes and tap/shower with hot water that will kill the bacteria.

Preventing Legionella in Commercial Washrooms

The 60015CP is a smart 15mm TMV (Thermostatic Mixing Valve) from Inta that features an integral diverter, allowing for the sterilisation of the valve and warm water supply pipework without disassembly. This helps to reduce the risk of Legionella and Legionnaires' disease.

The diverter can be periodically switched to allow hot water to flow into the body of the valve and through to the tap, to both Hot and Cold Feeds, therefore raising the temperature to that of the hot water supply. Once the sterilisation flush has finished, the diverter valve can be switched back to allow only blended, safe temperature water.

Thanks to the valve's temperature sensor, which dilates and contracts depending on the perceived temperature, it constantly sets the right proportion between hot and cold water, automatically regulating the water flow between hot and cold until the perfect temperature has been achieved.

MORE TO EXPLORE IN Related Posts

Delabie Compact Nano TMV3 Thermal Mixing Valve

Inta Intamix TMV3 Thermostatic Mixing Valve (15mm or 22mm)

Grohe Grohtherm Micro Thermostatic Mixing Valve (TMV)